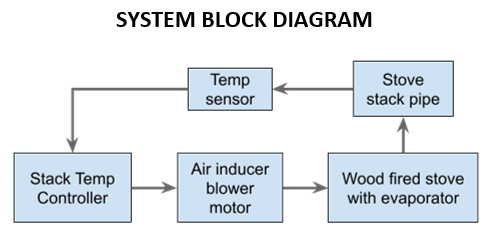

Some products on the market simply monitor the stack temp, which is important, but you still have the labor of maintaining the temperature. Even a master fire tender will experience fluctuations in the tens to hundreds of degrees. A common solution on the market is an AC blower motor controlled by a rheostat, but this has to be manually adjusted to account for varying wood species and moisture content. Not to mention, you have to manually adjust for cold loads and re-loads. The Stack Temp Controller addresses these issues, and more!

ADVANTAGES:

- Creates a more consistent boil and draw-off.

- Leads to a more consistent product.

- Improves efficiency (use less wood).

- Increases burn time.

- Reduces boil time.

- Adapts to different wood species.

- Adapts to varying moisture contents.

- Improves cold startup time.

- Improves re-load recovery time.

- Can be installed in about 10 minutes.

- Designed and built in the USA.

FEATURES:

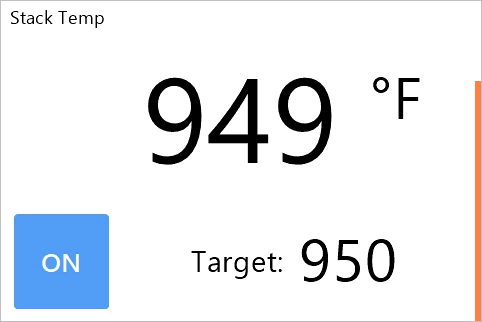

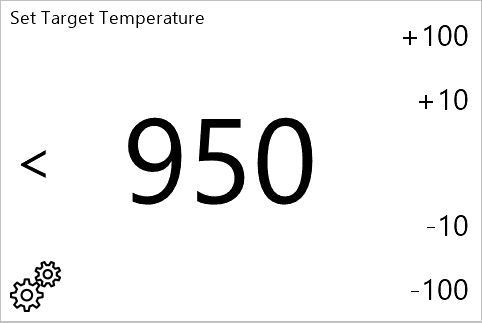

- Simple easy to use interface.

- Pluggable components for quick setup.

- Rugged resistive touchscreen.

- Touchscreen can be operated with gloves on.

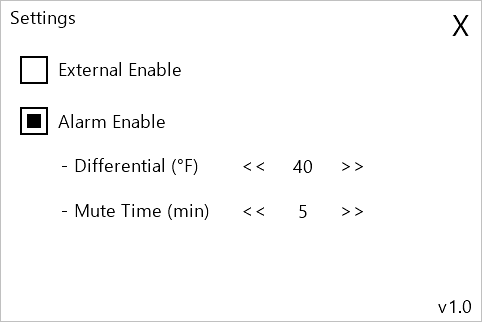

- Remote enable/disable switch capability.

- Configurable low temperature alarm (on-screen visual alarm).

- External alarm capability.

- Runs on 120 VAC power.

- Can run off of generator power.

- Able to run on a 12V deep cycle battery.

INCLUDED IN SYSTEM:

- 1 – Stack Temp Controller

- 1 – Blower Motor

- 1 – Thermocouple

- 1 – Power Supply

SPECIFICATIONS:

- Stack temp range: 0 – 2100°F

- Thermocouple:

- Type K.

- Maximum temp: 2100°F

- Integrated NPT fitting

- Controller ambient temp range: 0 – 110°F

- Blower motor: 12 VDC, 275 CFM

- Power Supply: 120 VAC in, 12 VDC out, 5A.

DISCLAIMERS:

- Remote alarm option: switch not included.

- External alarm option: device not included.

- Battery option: cable not included.

- For use with forced draft wood-fired arches only.

- CANNOT be used with an existing AC blower (must use the included DC blower).

- Arch must accept a standard Dayton blower flange (5.5″ x 5″).

DOCUMENTS:

Extensively tested and tuned for Smoky Lake maple syrup evaporators; however, the Stack Temp Controller uses it’s advanced algorithm to adapt to practically any forced draft evaporator. This adaptive algorithm has also been proven highly effective for outdoor force draft wood boilers, and will open to that market soon!

Smoky Lake evaporator: https://www.smokylakemaple.com/product/corsair-evaporator-w-drop-flue-pan-set-ssr-config-customize-it

D. Peterson, Lowell Vt (verified owner) –

Installed this system on my 2×4 drop flue pan. Garrett provided excellent support when i needed it. For me the benefits were a much quieter fan, and as noted above, lower stack temps at a given draw off rate. Less wood burned. Worked as promised.

Bulson Rd Natural Sweeteners (verified owner) –

We are in upstate New York boiling on a Leader 2×8 drop flue w a Revolution syrup pan. The first time boiling with this controller we immediately could see how much smoother and more consistent our draws were. Also, we found we boiled just as hard and produced the same rate of syrup at a 800 degree stack temp as we used to pushing our old fan at max and a 1000 degree stack. Those extra 200 degrees are wasted heat and wood!! Longer more consistent burns between reloading and the confidence of knowing exactly what we have beneath our pans. We run a 430 tap, high vacuum, operation w a 300gph home built RO. This controller takes a pretty efficient hobby setup to the next level! Garret has been extremely patient and helpful correcting an error I made during setup. His customer service commitment and timeliness in responding would be commendable at anytime, but is especially refreshing in the current environment. He has a friend and supporter in us forever!

Steve –

I was constantly messing with the AC blower that came with my Smoky Lake evaporator. This controller reduced my labor, and I’m using less wood!

Nick –

Works extremely well, total game changer. Keeps temp spot on and lets me know when wood is needed.